If you’re familiar with the legend of the Philosopher’s Stone, then this particular scenario may not seem so farfetched. This is a tale of a group of scientists who managed to transform material that costs just $100 per ton into something worth thousands and thousands of dollars per pound.

This particular team of scientists from Rice University embarked on a journey where they decided to convert coal – a relatively low-value energy source – into graphene. Graphene happens to be a very versatile raw material that boasts of various applications within the field of electronics.

This groundbreaking discovery has led them to realize that they could also employ a wide range of carbon sources for their experiments, which includes the unconventional choices of deceased cockroaches, coffee grounds, and even Girl Scout cookies.

Graphene, derived from the mineral graphite, represents a unique carbon allotrope, one of just two naturally occurring forms of carbon. Possessing metal-like properties, it holds immense value as a conductor in crucial sectors such as aerospace, medicine, and electronics.

According to the publication Medium, the global demand for this extraordinary material is projected to reach a staggering $1 billion, with an average market price of $67,000 per ton.

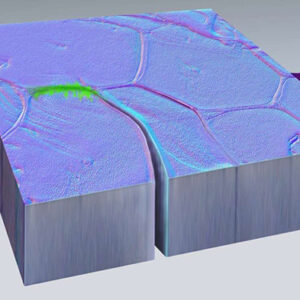

The scientists created their own technique, which they called “flash graphene” where they create high-value graphene flakes from an array of raw materials. This process involves connecting the materials to a pair of capacitors and electrodes, delivering a scorching 3,000° Kelvin shock.

According to Dr. James Tour, the lead researcher and a professor specializing in materials and nanotechnology at Rice University, this application works by passing a current through coal or trash with enough energy to break ‘every carbon-carbon bond in the substance before they recognize themselves as graphene.’

“You can put your finger right on the container a few seconds afterwards. And keep in mind this is almost three times hotter than the chemical vapor deposition furnaces we formerly used to make graphene, but in the flash process the heat is concentrated in the carbon material and none in a surrounding reactor,” said Dr. Tour.

This innovative approach allowed the team to generate graphene in substantial quantities.

“All the excess energy comes out as light, in a very bright flash, and because there aren’t any solvents, it’s a super clean process,” he said.

The conventional method of graphite mining carries significant environmental concerns, akin to other mining practices. However, the team identified two transformative aspects of bulk flash graphene production that could not only reduce the cost of various products but also substantially improve the environmental impact of manufacturing processes.

First, as detailed in the research paper authored by Dr. Tour and his team was published in Nature, the addition of just 0.1% of graphene to concrete could reduce its environmental footprint by a remarkable one-third.

Dr. Tour told his university press, “Essentially, we’re trapping greenhouse gases like carbon dioxide and methane that waste food would have emitted in landfills. We are converting those carbons into graphene and adding that graphene to concrete, thereby lowering the amount of carbon dioxide generated in concrete manufacture. It’s a win-win environmental scenario using graphene.”

Second, as explained in the accompanying video, existing coal mines and coal mining companies could redirect their product to flash graphene production instead of coal power plants. This strategic shift would eliminate the typical CO2 emissions stemming from coal combustion and, potentially, preserve thousands of jobs in the coal industry.

See more in the video below:

What are your thoughts? Please comment below and share this news!

True Activist / Report a typo